Steam Distillation of Essential Oils

Posted on 30 May 2025 by Ellemental Team — 6 min

Essential oils have been treasured for centuries for their aromatic and therapeutic properties, forming a cornerstone of modern aromatherapy and natural cosmetics. Among the various extraction techniques employed, steam distillation stands out as the most widely used and time-honored method for obtaining high-quality essential oils from plant material.

In this in-depth guide, we explore the principles, processes, equipment, advantages, and limitations of steam distillation. We also provide insights into how the quality of essential oils is influenced by this method, what parameters should be controlled, and what to consider when sourcing steam-distilled oils for cosmetic use.

1. Understanding Steam Distillation

Steam distillation is a separation process used to isolate temperature-sensitive compounds, such as essential oils, from plant material. It relies on the principle that when steam passes through the botanical matter, it volatilizes the aromatic compounds. These volatile constituents are then condensed back into a liquid form and separated based on differences in density.

Key Principle:

When steam is introduced into a system containing plant matter, it lowers the boiling point of essential oil constituents, enabling their vaporization without degrading thermally sensitive molecules. This makes steam distillation ideal for extracting oils from delicate flowers, leaves, seeds, and roots.

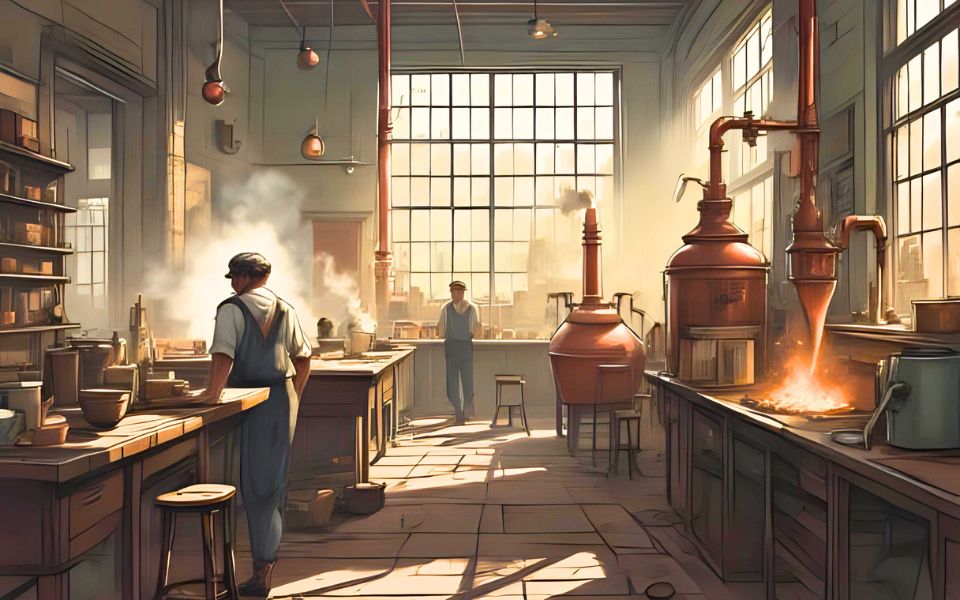

2. Historical Context

The origins of steam distillation can be traced back to ancient Persia and Egypt, where rudimentary distillation systems were used for perfume and medicinal extracts. Avicenna (Ibn Sina) is credited with refining the technique in the 10th century to extract rose oil. Since then, the method has evolved into a scientific process used at both artisanal and industrial scales.

3. Equipment and Setup

Steam distillation systems vary in complexity—from traditional copper stills to advanced stainless-steel apparatuses—but the core components remain the same:

Basic Components:

- Still Pot (Boiler): Holds the plant material and produces steam.

- Retort/Separator: Where the steam contacts the plant material.

- Condenser: Cools down the vaporized mixture.

- Separator (Florentine Flask): Collects the condensate, separating the essential oil from hydrosol based on density.

In more sophisticated systems, pressurized steam generators, vacuum pumps, and temperature control units are employed to enhance efficiency and yield consistency.

4. The Process of Steam Distillation

Step-by-Step Overview:

- Preparation of Raw Material

- Plant material is harvested at peak maturity and often chopped or shredded to increase surface area for steam contact.

- The material should be fresh or properly dried to avoid microbial contamination or hydrolysis of components.

- Steam Generation

- Steam is introduced either directly (direct steam distillation) or indirectly via a steam jacket or coil (indirect steam distillation).

- In hydro-distillation variants, plant matter is submerged in boiling water, although this is less gentle.

- Volatilization of Compounds

- Steam permeates the botanical matrix, vaporizing the essential oil constituents without exceeding their normal boiling points.

- Condensation

- The vapor passes through a condenser where it cools down and reverts to a liquid state.

- Separation

- The mixture of water and essential oil enters the separator. Since most essential oils are hydrophobic and lighter than water, they float and can be decanted. Oils denser than water (e.g., cinnamon bark oil) sink and are collected from the bottom.

5. Parameters Influencing the Yield and Quality

a. Steam Temperature and Pressure

- Maintaining an optimal range (typically 100–105°C) ensures efficient vaporization without thermal degradation.

- Overheating can result in decomposition or alteration of key constituents (e.g., monoterpenes).

b. Distillation Duration

- Prolonged distillation may yield more oil but can also extract undesirable fractions or result in a flat, less vibrant aroma.

c. Plant Material Quality

- Freshness, botanical species, part used (flower, root, leaf), and time of harvest significantly affect oil composition and yield.

d. Particle Size

- Finer particles allow more surface contact with steam but may also clog equipment or lead to emulsion formation in the separator.

e. Cooling Rate

- Efficient condensation is essential to avoid losses of low-boiling components, particularly with delicate oils like neroli or ylang-ylang.

6. Advantages of Steam Distillation

- Preserves Bioactivity: Gentle enough to retain most of the plant’s active volatile compounds.

- Scalable: Suitable for both small-scale artisanal production and large-scale industrial operations.

- Low Residue: No need for chemical solvents, making the resulting oils purer and safer for cosmetic use.

- Yields Hydrosols: Valuable aromatic waters are produced alongside essential oils.

7. Limitations and Considerations

- Not Suitable for All Plants: Some resins, barks, and fatty plant materials require solvent or CO₂ extraction.

- Thermal Sensitivity: Overheating or extended distillation may degrade delicate molecules such as esters and aldehydes.

- Water Solubility Losses: Certain light constituents may dissolve into the hydrosol, reducing overall yield.

8. Steam-Distilled Oils in Cosmetic Applications

Steam-distilled essential oils are widely used in natural cosmetics for their:

- Aromatic properties (fragrance, sensorial experience)

- Functional benefits (anti-inflammatory, antimicrobial, antioxidant effects)

- Skin compatibility, especially when properly diluted in carriers

Popular steam-distilled oils in cosmetics include:

- Lavender (Lavandula angustifolia): Soothing and regenerating.

- Tea Tree (Melaleuca alternifolia): Purifying and anti-acne.

- Rosemary (Rosmarinus officinalis): Stimulating, often used in hair care.

- Geranium (Pelargonium graveolens): Balancing and toning for skin.

Always verify that oils are 100% pure, chemotyped, and accompanied by a GC-MS report (Gas Chromatography-Mass Spectrometry) to ensure transparency and quality.

9. Buying and Sourcing Considerations

When purchasing steam-distilled essential oils for personal use or cosmetic formulation, consider the following:

- Botanical Name & Chemotype: Ensure the correct species and chemical profile for the desired effect.

- Distillation Method & Duration: Some producers offer oils from first distillation (considered higher quality).

- Origin & Sustainability: Opt for ethically harvested and certified organic sources where possible.

- Documentation: Look for COA (Certificate of Analysis), IFRA compliance, and allergen reports.

Beware of Common Pitfalls:

- Adulteration: Some oils are extended with synthetic analogs or cheaper oils.

- Mislabeling: Avoid vague labels that don’t specify distillation method or plant part.

- Exaggerated Claims: Be skeptical of oils marketed with curative health claims.

10. Conclusion

Steam distillation remains a cornerstone method in the extraction of essential oils, offering a balance of tradition, efficiency, and purity. For formulators, aromatherapists, and enthusiasts alike, understanding the nuances of this process is essential to appreciating the true value and complexity of essential oils.

When handled with care, and sourced responsibly, steam-distilled oils not only deliver potent botanical benefits but also support a sustainable and clean approach to cosmetic formulation.